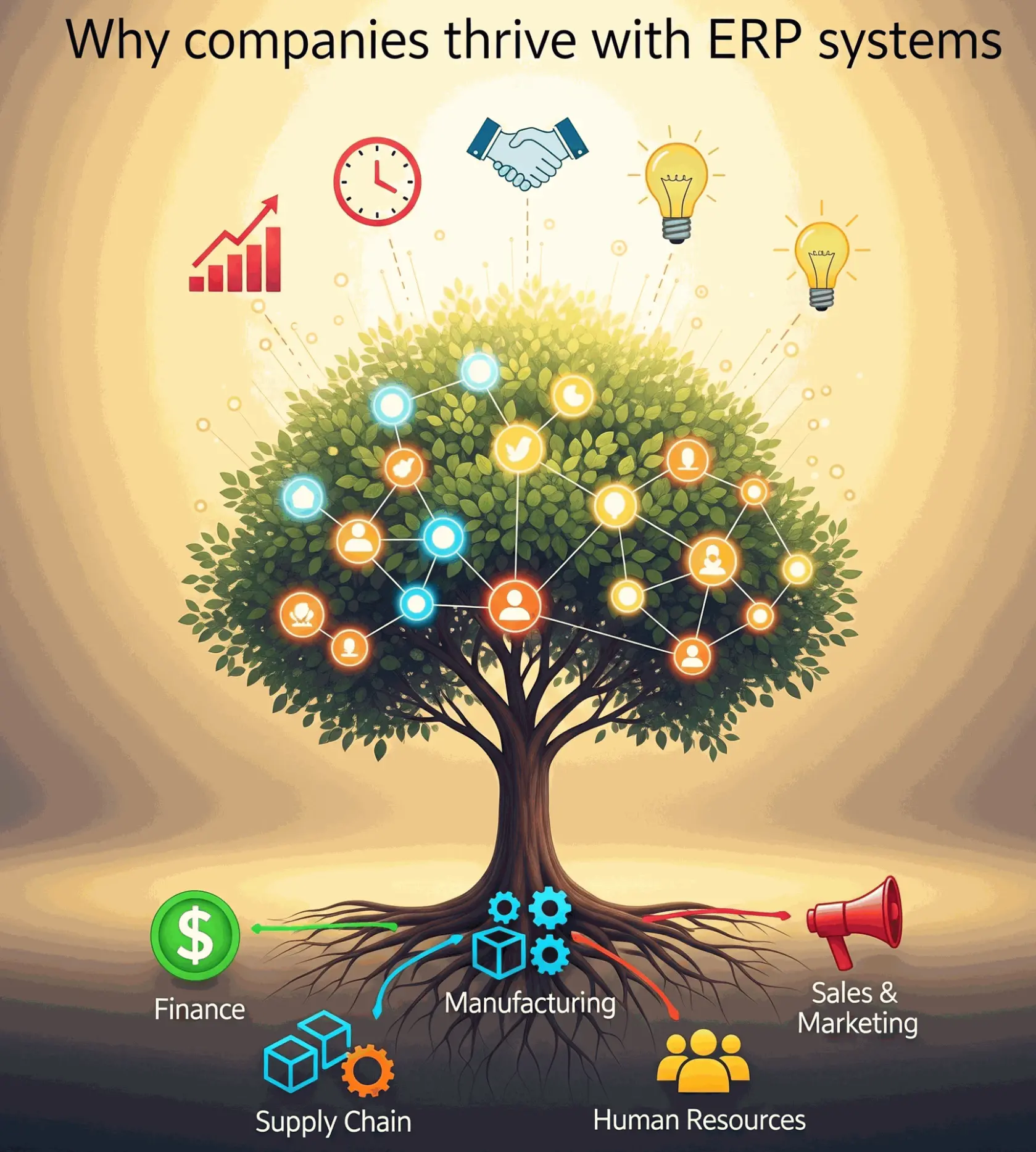

Businesses use Enterprise Resource Planning (ERP) systems because they act as the digital backbone of modern organizations, integrating and centralizing various facets of operations to achieve enhanced efficiency, informed decision-making, and sustainable growth. ERP systems aim to streamline and automate business processes, provide a single source of truth, and offer complete visibility into every business area.

Key reasons why organizations leverage ERP systems

Enhanced Operational Efficiency and Cost Reduction

- Streamlined Processes and Automation. ERP systems automate routine tasks and eliminate manual data entry, significantly reducing errors, optimizing resource allocation, and cutting down on administrative expenses. This includes automating work order generation, invoice management, and supply chain activities.

- Real-time Production Monitoring. They provide instant updates on production orders, allowing for quick decisions to address bottlenecks, optimize resource allocation, and facilitate immediate quality control.

- Effective Inventory Management. ERP systems track raw materials, work-in-progress, and finished goods in real-time, enabling accurate inventory levels, automated reordering, and cost control by reducing overstocking or under-stocking.

- Cost Tracking and Analysis. Manufacturers can meticulously track and allocate costs to specific products or processes, manage budgets, and perform variance analysis to maintain profitability and identify cost-saving opportunities.

- Labor and Equipment Optimization. ERP helps optimize workforce allocation based on skills and tasks, and monitors machinery utilization to reduce downtime and maintenance costs.

Improved Data Accuracy and Informed Decision-Making

- Unified Data Platform. ERP systems integrate and centralize various operations onto a single platform, ensuring a single version of the truth and eliminating misinformation across departments. Data collected by one department is instantly available to others who need it.

- Real-Time Reporting and Analytics. They provide immediate access to Key Performance Indicators (KPIs) and customizable reports, offering up-to-the-minute financial insights and allowing for informed, data-driven decisions.

- Business Intelligence (BI) and Predictive Analytics. BI tools enable data visualization, trend analysis, and predictive analytics to forecast future trends and outcomes, aiding proactive decision-making and better preparation for market fluctuations.

Enhanced Supply Chain Management

- Comprehensive Visibility. ERP systems offer enhanced analytics across the supply chain, streamlining operational systems and data to align supply and demand effectively. They provide full visibility into inventory data and track product movement.

- Supplier Collaboration. Features like supplier portals and automated ordering facilitate seamless communication and procurement, reducing stock-outs and ensuring a steady supply of materials.

- Accurate Demand Forecasting. By analyzing historical sales data and market trends, ERP systems generate accurate demand forecasts, crucial for production schedules and inventory optimization.

- Streamlined Order Fulfillment. ERP systems can automate invoicing, record shipment details, and conduct quality control checks, ensuring timely dispatch and a more personalized customer experience.

Improved Quality Control

- Quality Assurance Modules. ERP often includes modules to define and enforce quality standards, enable real-time inspections, and facilitate documentation and traceability throughout production, reducing defects.

- Traceability and Recall Management. They allow for lot and serial number tracking, streamlining product recalls and providing data for root cause analysis to prevent future issues.

Boosted Productivity and Collaboration

- Workforce Management. ERP optimizes resource scheduling, tracks employee skills, and simplifies time and attendance tracking, contributing to higher productivity.

- Continuous Improvement. By providing data for analysis and supporting feedback loops, ERP systems foster a culture of continuous improvement, identifying bottlenecks and inefficiencies.

- Rapid Prototyping and Project Management. They expedite prototyping through integration with 3D modeling and simulation software, and offer robust project management capabilities for scheduling, resource allocation, and milestone tracking.

Ensuring Compliance and Regulation Adherence

- Regulatory Reporting and Audit Trails. ERP systems automate the generation of compliance reports, ensure data accuracy, and maintain detailed audit trails of data changes and user actions, essential for demonstrating compliance and supporting audits.

Enhanced Equipment and Maintenance Management

- Preventive Maintenance and Asset Management. ERP includes features for preventive maintenance scheduling to reduce unscheduled downtime and asset management integration for real-time visibility and integrated costing of high-value equipment.

Driving Digital Transformation and Future-Proofing

- IoT and Smart Factory Integration Modern. ERP systems integrate with IoT technologies to collect data directly from machines, monitor performance metrics, and enable predictive maintenance.

- Mobile Accessibility. Many solutions offer mobile access, allowing supervisors and managers to input data, receive updates, and track KPIs from anywhere, enhancing agility.

- Support for Strategic. Planning Features like Master Production Scheduling (MPS) and Sales and Operations Planning (S&OP) help align manufacturing with demand, balance supply, and facilitate cross-functional collaboration for agile planning.

- Global Operations and Business Continuity. For international businesses, ERP supports multi-currency, multi-language, and global compliance, while cloud-based solutions offer built-in business continuity through automated data backups and system redundancy.

- Scalability. ERP systems are designed to scale with business growth, allowing organizations to add modules and accommodate heavier volumes, more resources, and more users as needed.

- Integration of New Technologies. ERP is increasingly integrating with advanced technologies like AI and machine learning for automation and predictive analytics, and Blockchain for immutable record-keeping and data checks, preparing businesses for future trends.

Businesses often realize they need an ERP system when they face challenges such as difficulty managing day-to-day processes, a reliance on paper-based or manual tasks, using multiple disconnected applications, struggling to access critical information and analytics, or experiencing complicated business processes that hinder growth. By addressing these pain points, an ERP system ultimately helps businesses expand, increase revenue, reduce working capital, and serve customers better.